Ferroelectric Plasma Sources

Ferroelectric plasma sources (FPS) is a new but rapidly growing field in low temperature plasma science and technology. It originated from high current ferroelectric cathodes, discovered by Gundel, Riege, and co-authors in 1989. It has been shown that in vacuum the application of a driving pulse of a few kV, between solid rear electrodes and patterned front electrodes, which cover a sample of a ferroelectric ceramic, results in electron emission from the side of the front electrode. The current density of this electron emission varies from tens of mA to hundreds of A per cm2, depending on various experimental conditions: the polarity, the amplitude, and the shape of the driving pulse; the pattern geometry and the composition of the front electrode; the thickness and the composition of the ferroelectric ceramics; and the amplitude, the duration, and the time delay of application of the extracting voltage. Vacuum ferroelectric cathodes are able to produce uniform electron beams with low beam divergence, without delay of the beam appearance with respect to the accelerating voltage application, and without significant vacuum deterioration. These features make ferroelectric cathodes very promising for powerful microwave devices like gyrotrons, magnetrons, and TW tubes, which are all operated at accelerating fields less than 50 kV/cm.

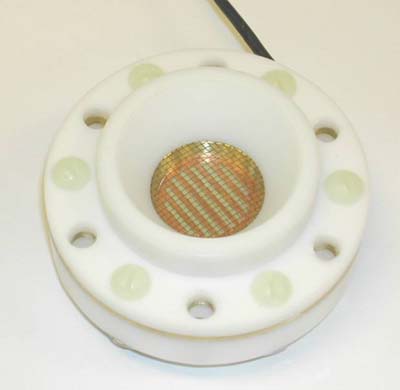

Ferroelectric Plasma Cathode

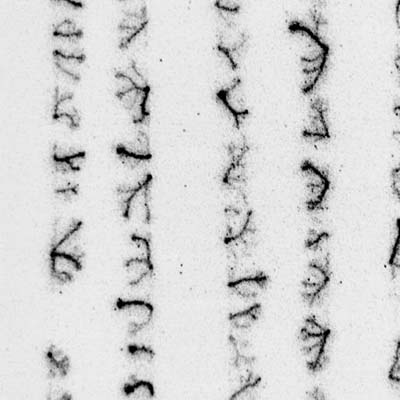

High current mode of ferroelectric cathode operation was found to be related to surface discharges formed on the ceramic surface near the edges of the front electrode pattern. These discharges are initiated by field emission from the triple junctions at the edges of the patterned front electrode. Electric field of the applied driving pulse is strongly nonuniform at the triple junctions and enhanced by polarization charge induced at the surface of ferroelectric material. Electron avalanches along the surface lead to the plasma formation. This surface discharge plasma has a density of about 10×12 cm-3, an electron temperature of 2-3 eV, and consists mostly of the materials of ferroelectric ceramics and the front electrode. Such an ablative FPS has a lifetime limited by either surface erosion or chemical changes in the surface compounds.

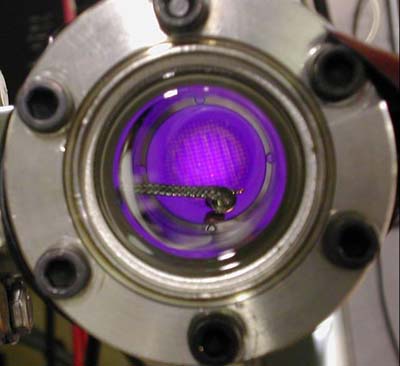

Gaseous Ferroelectric Plasma Source at Operation

The ability of ferroelectric materials to build up substantial polarization charge in reaction of the driving voltage application, together with patterned structure of the front electrode, which causes nonuniformity in surface distribution of this polarization charge, can be also used to ignite and sustain gaseous discharges in wide pressure range. At PPPL, we are studying gaseous FPS. We found that at pressures higher than several Torr the surface discharge turns completely into gaseous discharge with a plasma density of ~10×15 cm-3. This discharge is obviously ignited by electron emission from triple junctions, but later the discharge dynamics might be determined by sheath behavior with the presence of the surface polarization charge. Presently, we are investigating plasma parameters of gaseous FPS in various configurations. Our study of vacuum FPS is focused on operation of FPS in magnetic fields. Both gaseous and vacuum FPS could be adopted in Hall thrusters and for new types of plasma propulsion devices and other aerospace applications.

Surface Discharges on Vacuum Ferroelectric Plasma Source

Contact Alexander Dunaevsky for more information about this project.